Mini Plan Sifter

Purpose: To separate mixed particle sizes through one machine

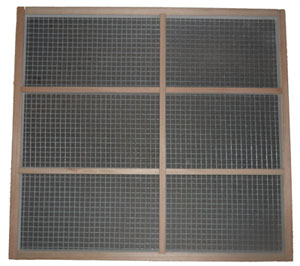

Mini Sifter Complete

Result:

- Very course

- Course

- Medium

- Fine

Scope:

- Utilized where granular, flowery and powder like products are produced (with low moisture content)

- Popular in the food industry i.e. Production of:

- Mielie meal

- Cake flour

- Bread flour

- Rice

- Soya

- Animal feed

- Other industries which may benefit from the mini are:

- Chemical

- Explosives

- Mining

- Rubber

- Plastics

- Most industries, where size reduction takes place

DESCRIPTION:

The machine consists of three major components i.e.

- Inner frames, also known as the clothing frames

- Outer sieve boxes

- Drive unit

- Inner Clothing Frames

- Fabricated from high quality timber

- Lined with hard wearing formica

- Accommodates the brushes, backing wire and the screen

- The brushes promote self cleaning

- Outer sieve boxes

- Fabricated from high quality timber

- Internally lined with hard wearing Formica

- Accommodates the aluminum skid plates, and forms the flow passages

- The inner clothing frames fit neatly into the outer boxes

- Complete plan sifter box

- Drive Unit

- Fabricated from mild steel plate (or stainless steel pending customer requirement)

- Accommodates the motor (0,75kw) bearing housing and fly wheel (belt driven)

- The outer sieve boxes fit snugly on top of the drive unit

- This unit creates the circular motion

- Assembly

- The drive init and sieve boxes are suspended in a square tubing frame utilizing canes

WORKING PRINCIPLES

- Product enters at the top of sieve boxes

- Utilizing gravity, it then flows through the boxes to exit below

- After entering, the product flows over the screens, also known as covers

- The particle, larger than the screen aperture, flows over to the next screen

- That which is smaller than the aperture falls through onto the aluminium skid plate, from where it is channeled out or onto a finer screen

- The process is repeated, numerous times in so doing obtaining maximum efficiency

- Spout fittings below, provide access for obtaining samples of the sieved product

Mini Sifter Complete

SYNOPSIS

The mini plan sifter is a non-complicated machine with low maintenance, suitable for industries where size reduction is executed

Leave a Reply

You must be logged in to post a comment.